Field of Application

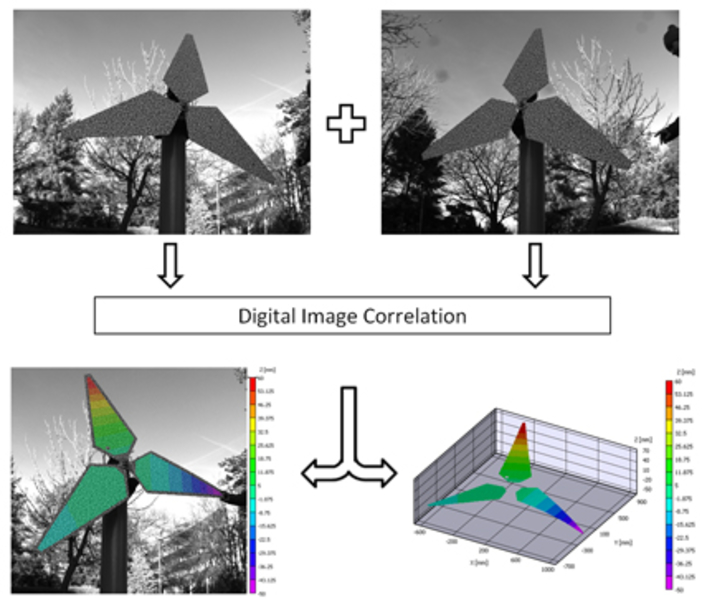

- Contactless measurement of surface deformations in rotating machinery

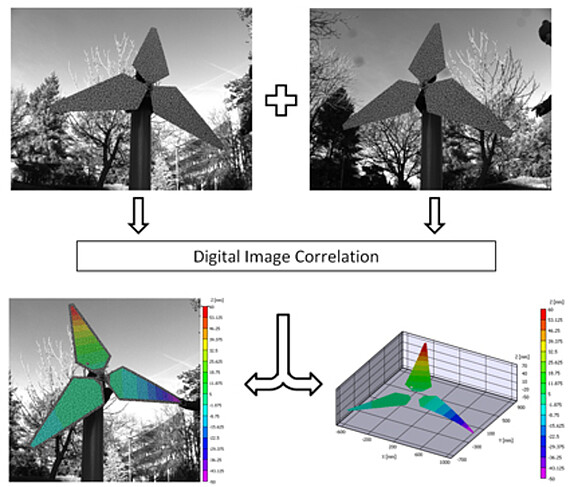

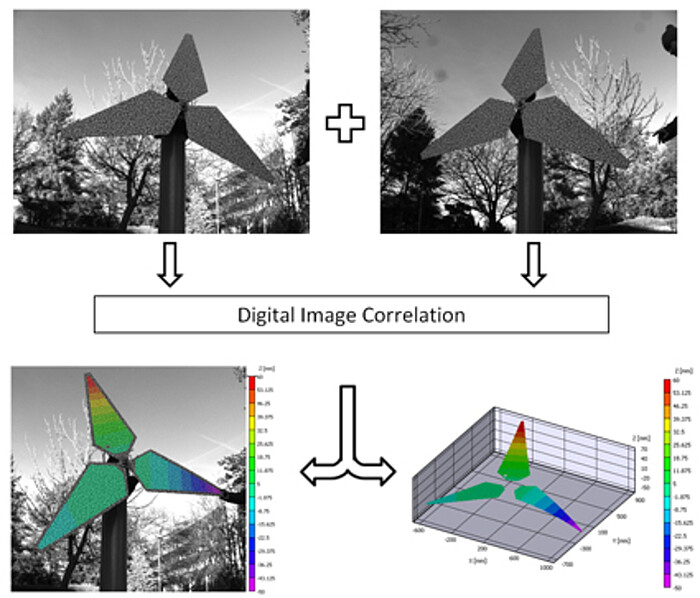

- Measurement of rotor blade deformations on wind turbines in operation

- Stress analysis and modal analysis on machine components

Description

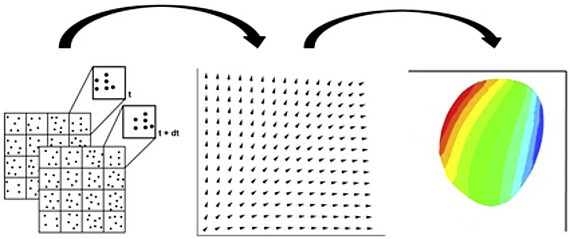

Starting from a reference image, the movement of the surface over time relative to the reference is determined. By isolating or eliminating the rigid body motion, the strain can be calculated and, with the help of material laws, the stress on the component surface. Likewise, large-scale vibration analyses on stationary and rotating components are possible through the use of high-speed cameras.

The basic requirement for the use of Digital Image Correlation is a random, high-contrast, non-reflective surface texture. If the natural texture of the surface does not meet these requirements, artificial textures can be applied. The possibilities range from printed foils, to sprayed-on textures, to surfaces wetted with toner.

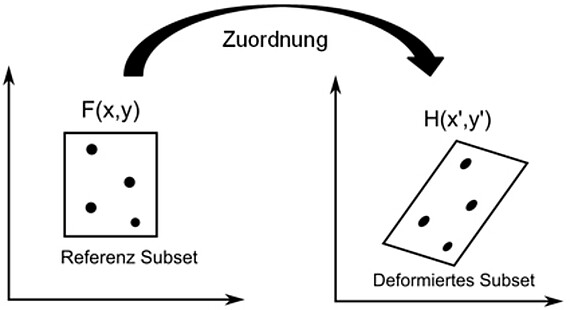

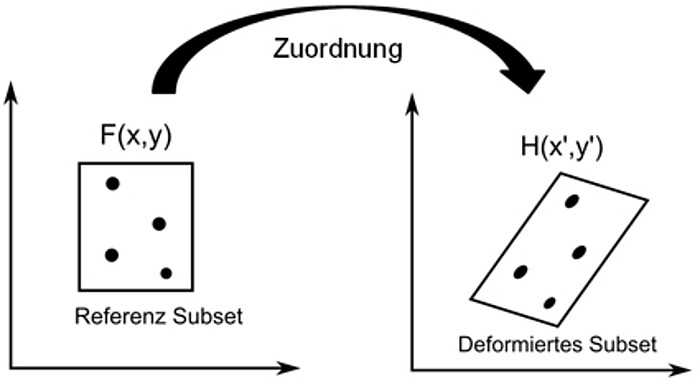

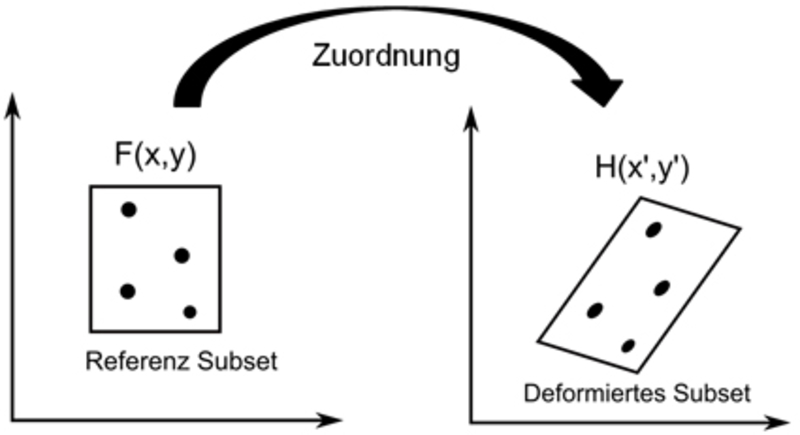

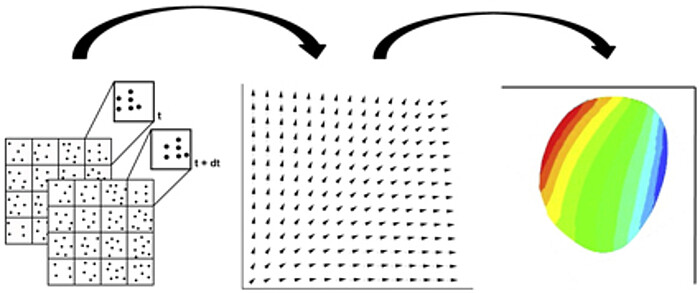

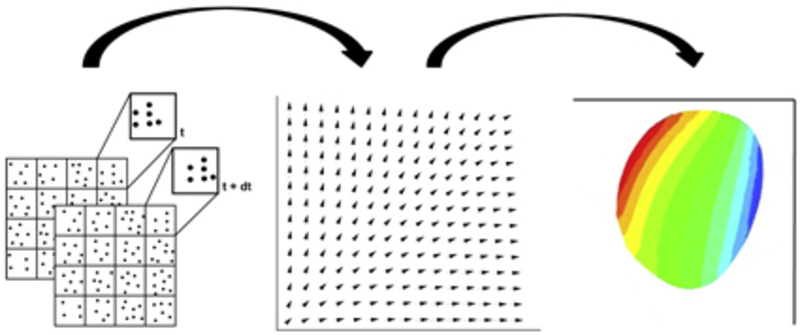

To evaluate the measurement images, the random texture of the surface in the reference image is discretized into windows (also called "subsets"). These subsets are then assigned to each image in the measurement series using a correlation method. The result is a vector field that assigns a displacement to each subset relative to the reference. By using subpixel interpolation, movements in the image down to 0.01 pixel can be detected.

The method works both with only one camera in two-dimensional space and in three-dimensional space with at least two cameras. When using a single camera, the camera's line of sight must be perpendicular to the surface being examined and only in-plane motion can be detected. Two cameras, on the other hand, allow tracking of a surface in three-dimensional space. In addition, for two or more cameras, the restriction of the perpendicular viewing direction to the surface does not apply. Even relatively acute viewing angles to the surface can often be realized.

Measurement Parameter

- Deformation

- Elongation

- Stresses

- Absorption

- Frequencies (FFT)