1831 - Founded as a Higher Vocational School

The school was initially located centrally, in Bornemann's House, and had the fields of study: Mathematics, Geometry, Architecture, Mechanical Engineering, Natural History, Physics, Chemistry, Technology, Drawing, Bossing and Bookkeeping. There were 64 enrolled students. The director was 28-year-old Karl Karmarsch from Vienna.

1879 - Elevation to the Royal Technical University and Move to the Welfenschloss (Guelph Castle)

By constitutional reform in 1879 the name Technical University and a division into 5 departments were introduced: Architecture, Civil Engineering, Mechanical Engineering, Chemistry and Electrical Engineering, and General Sciences.

1900 - Division into Faculty of Civil Engineering and Faculty of Mechanical Engineering

In the 19th century, engineering mechanics had been developed from structural and machine dynamics and analytical mechanics and was assigned to the Faculty of General Sciences. In 1900, this field was divided into two chairs, Faculty of Civil Engineering and Faculty of Mechanical Engineering.

1922 - Founding of a mechanical engineering department in the Faculty of Mechanical Engineering

In 1922, a Department of Mechanical Engineering was founded within the Faculty of Mechanical Engineering. It comprised several departments, including technical thermodynamics, combustion engines and refrigeration machines, technical mechanics and aerodynamics, strength of materials and machine elements. Hydroelectric machines were headed by Oesterlen from 1913, while steam engines were headed by K. Röder from 1926. Other areas included hoisting machines, hoists and pumps, railroad machines and railroad operation as well as mechanical technology, metallography and fiber technology. Agricultural machinery and the areas of machine tools, manufacturing and business organization rounded off the extensive range of products.

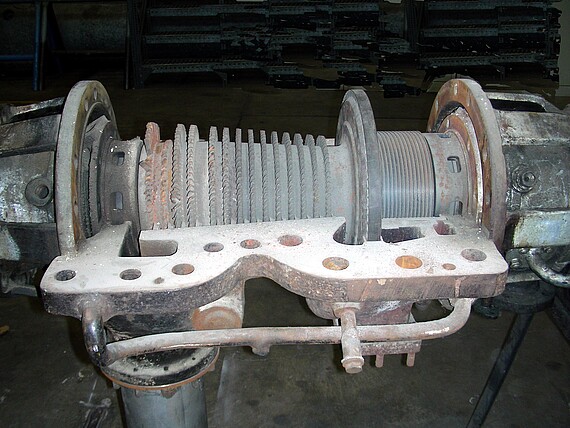

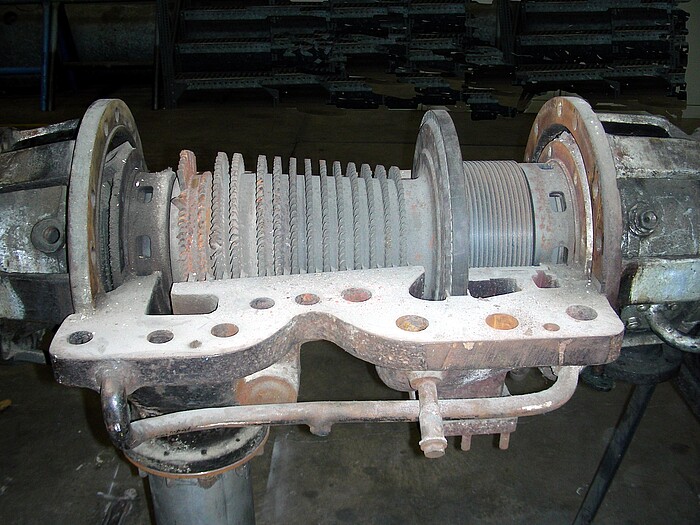

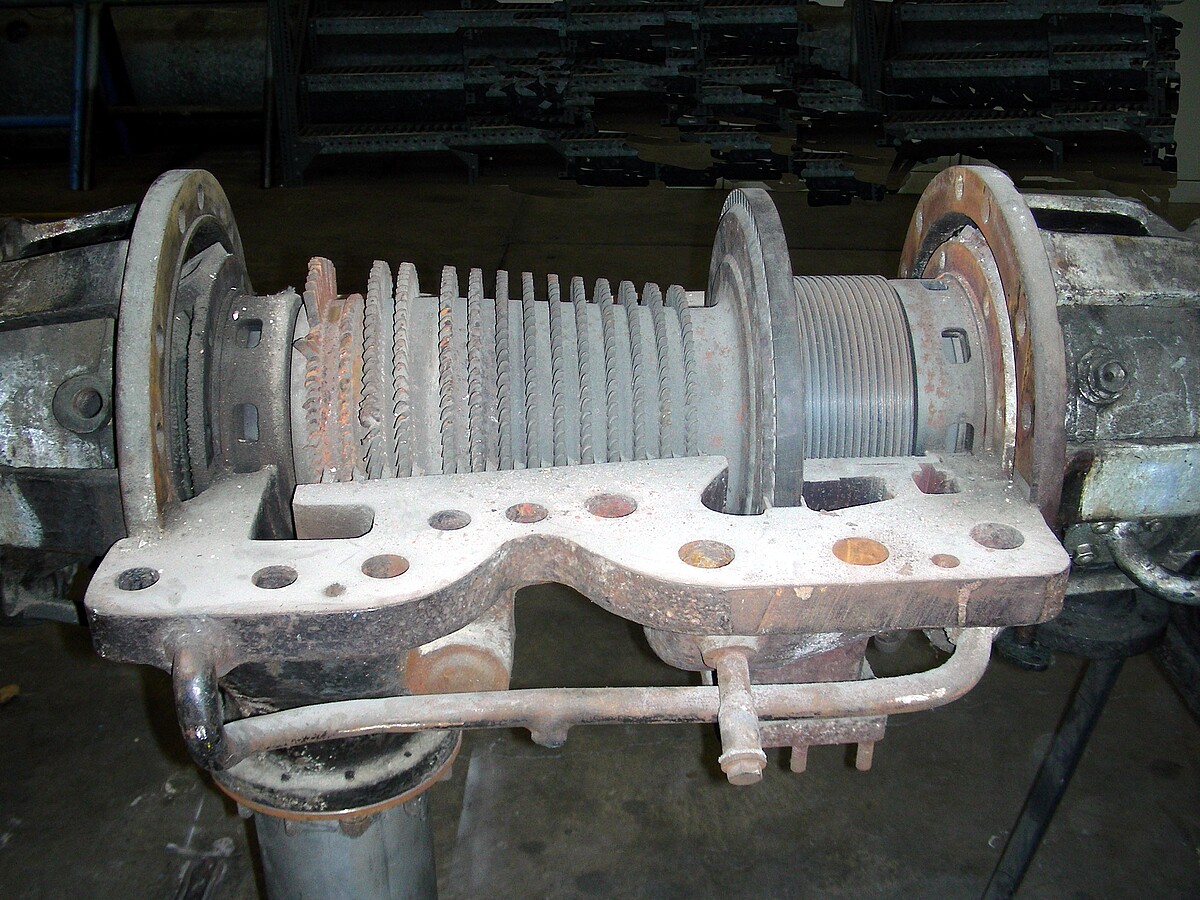

1938 - Innovation of the Röderturbine

Karl Röder set new standards in steam turbine technology in 1938 with the development of the high-speed axial overpressure turbine, known as the Röder turbine. This turbine, equipped with the innovative “breathing internals”, solved a long-standing problem through high thermal elasticity, fast start-up and steep load gradients.

His pioneering work began as early as 1914, when August Thyssen brought Röder to Mülheim/Ruhr. The first 3000-turn large turbine of the Thyssen-Röder design was built there. A further significant advance followed in 1928 with the axial counter-rotating turbine, the first commercially viable steam turbine of axial design. These developments laid the foundation for Röder's later success.

Today, a restored test turbine from the university's former combined heat and power plant in the exhibition area of the institute is a reminder of Röder's visionary work - a testimony to his decisive contributions to the development of the Röder turbine.

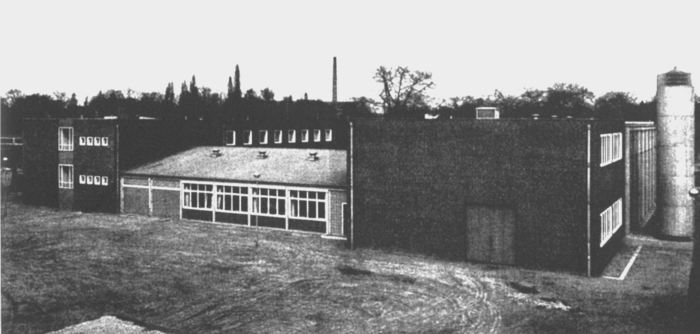

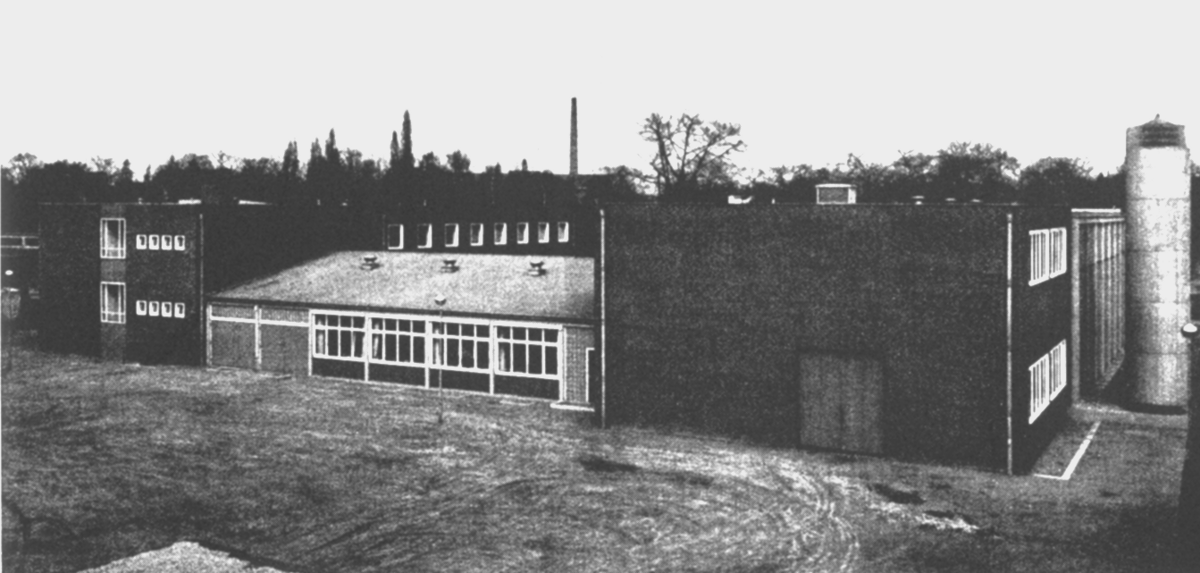

1958 - New institute building Appelstraße

Karl Bammert's appointment in 1955 laid the foundation for today's Institute of Turbomachinery and Fluid Dynamics. At that time, the institute was spread over five different locations on the grounds of the Technical University. Gustav Flügel jokingly offered Bammert the front of his large desk as a workplace. The construction of a new institute building was one of Bammert's central tasks.

In 1958, the state of Lower Saxony provided DM 1.5 million for the construction. The appointment agreement stated that Bammert was to provide the Institute with the necessary equipment without additional state funding. Thanks to his research successes and his powers of persuasion, he succeeded in raising almost six times this sum from industry and research institutions.

The construction of the office building commenced in September 1958, with the building becoming fully operational in 1960. The entire building was completed and celebrated in March 1962. Further facilities were subsequently added in the following years: measuring cabins and a cooling tower in 1968, further measuring cabins and a filter chamber in 1972, and a special measuring cabin for turbines in 1974.

The institute boasts an extensive array of test rigs, encompassing plane lattice wind tunnels, wind tunnels, a rotationally symmetrical lattice wind tunnel, multi-stage axial test turbines, and test compressors. Additionally, radial test compressors and turbocharger test benches are available for utilisation. Calibration channels capable of supplying compressed air up to 8 bar and up to 11 kg/s, in conjunction with a Leonard direct current system capable of up to 2.4 MW, facilitate comprehensive testing capabilities.

2019 - Relocation to Garbsen

In 2019, the Institute of Turbomaachinery and Fluid Dynamics - TFD moved to the new campus of the Faculty of Mechanical Engineering. The approximately 20,750 square meter area houses three institute buildings for twelve institutes, the research building Dynamics of Energy Conversion, a lecture hall building, a refectory, a house for students with seminar rooms and workrooms, and a technical building. Across from the new building, seven mechanical engineering institutes have been located since 2004 as the Production Technology Center (PZH).

To enable students to learn and researchers to experiment on what was once a greenfield site, workers had to move and excavate in advance: 25,000 cubic meters of soil, 6,650 vibro-tamping columns were set to stabilize the building ground, 4,500 tons of steel, 23,600 cubic meters of concrete, 2,100 precast concrete parts, 80,000 square meters of plasterboard, 3,000 square meters of cement board were installed, 1,000 kilometers of cable were laid in cable trays, and 1,800 windows and 550 doors were inserted.

©

Michael Gaßner, Atmo-TV

©

Michael Gaßner, Atmo-TV