Design of turbomachinery

Development and evaluation of machine designs

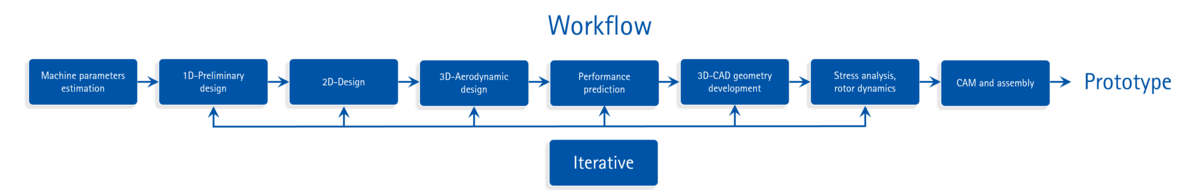

Machine designs are evaluated on the basis of clearly defined criteria such as efficiency, pumping limit distance and mechanical stresses. Both numerical simulations and simplified models are used here. Sensitivity analyses help to identify critical parameters and improve the designs in a targeted manner. Dynamic parameterization enables flexible adaptation to specific requirements, which ensures more precise evaluations and an efficient workflow.

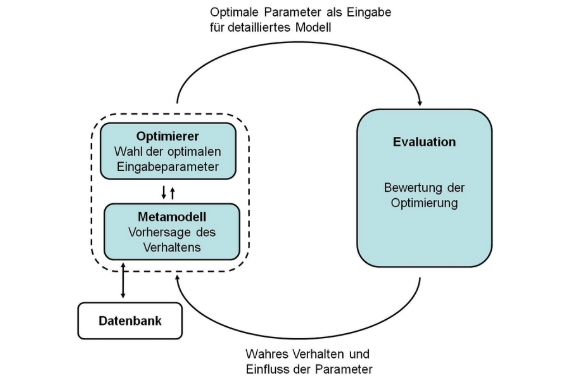

Automated optimization of turbomachinery

We rely on automated sensitivity analyses and optimization methods for the optimal design and improvement of turbomachinery. These approaches enable precise parameterization and evaluation of machine designs, while the level of detail can be flexibly adapted. In order to reduce the time required for numerical simulations, we use substitute models (meta-models) that exclude inefficient designs at an early stage. These models are continuously updated to provide you with the most efficient solutions and accelerate development processes.

Pareto optimum as the result of optimization

Our optimization methods lead to a Pareto optimum - a variety of designs that represent an ideal compromise between the defined criteria. Sensitivity analyses help to weight the decisive parameters and find the optimum balance. No design within the Pareto optimum can be improved without negatively influencing other criteria. By specifically weighting the criteria, we select the best design for your specific requirements, which enables sound and targeted decision-making.

Do you need support with the design of your machine? Please contact us!

30823 Garbsen