Description

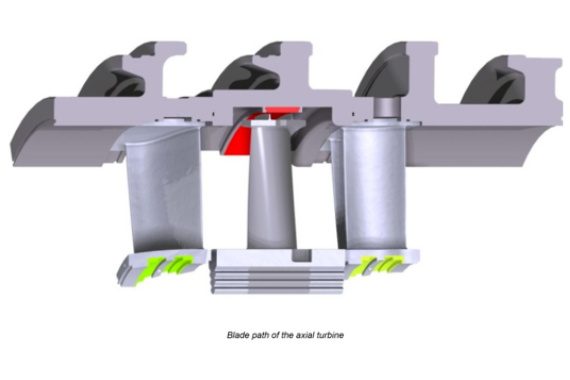

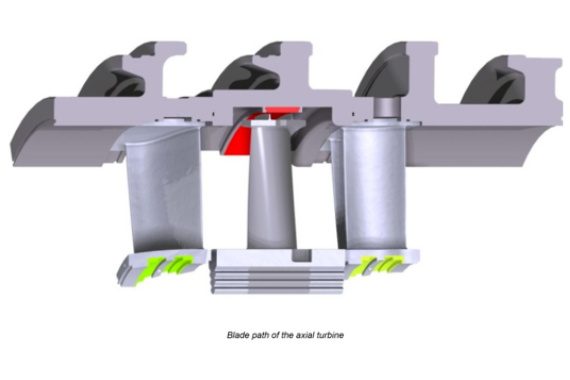

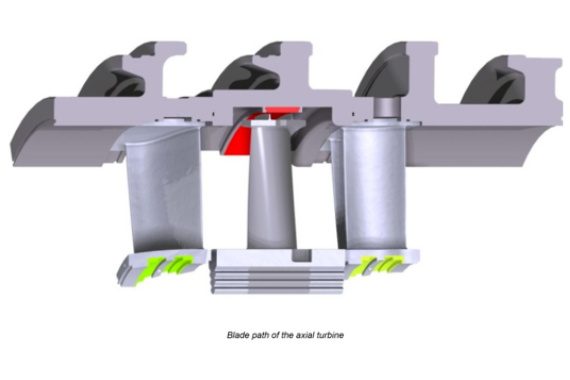

Component design

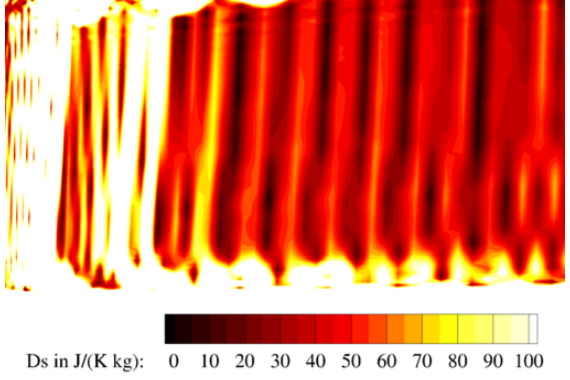

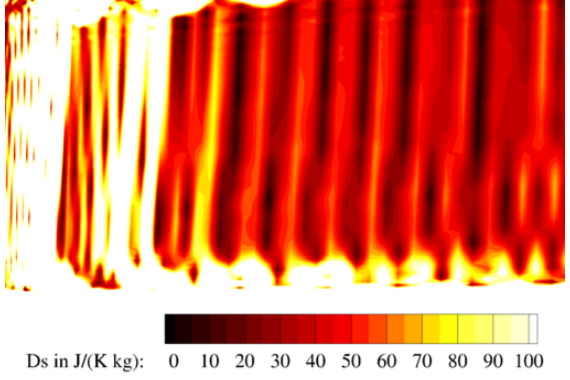

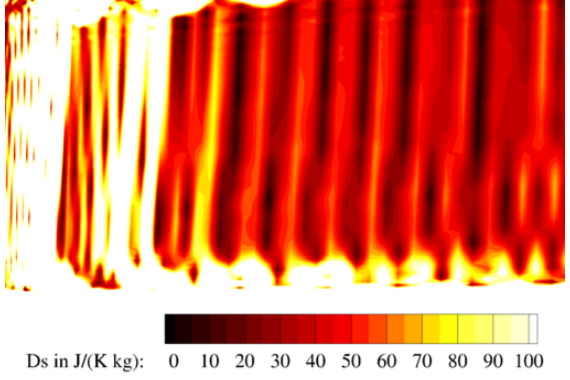

One focus of our work is the improvement of turbine components to increase efficiency. For example, we deal with the interaction of leakage and main flows in shrouded turbines. Here, mixing losses can be minimized through targeted secondary air injection and non-axisymmetric sidewall contours. In addition, we consider the interaction with adjacent components, such as the effect of support ribs on the secondary flow in annulus diffusers and the transient rotor-stator interaction, in order to identify their influence on the work turnover and efficiency.

Flexible operation of turbines

Gas turbines in flexible load operation are essential for grid stabilization. In this context, we are investigating low-load flows and their influence on the service life of the turbine. We are also investigating ways of improving operational stability and minimizing installation space. We achieve this by optimally coordinating the turbine and diffuser in both full and part-load operation.

Efficient maintenance and repair

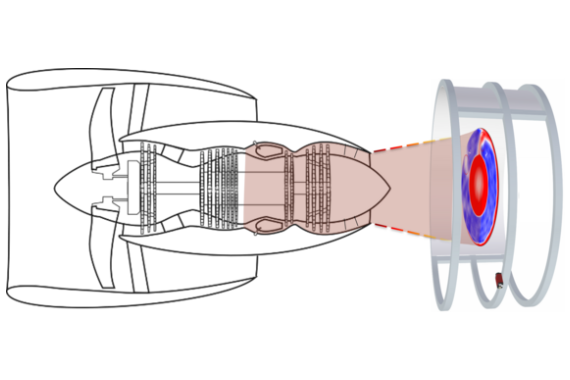

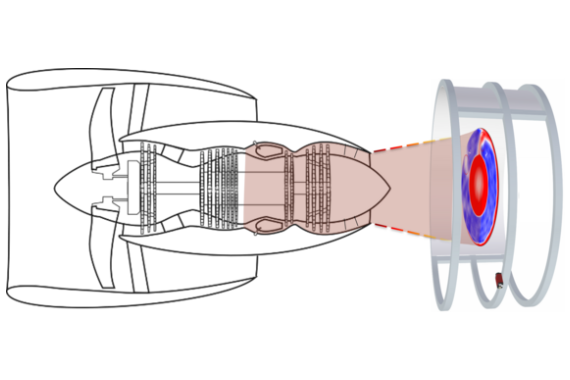

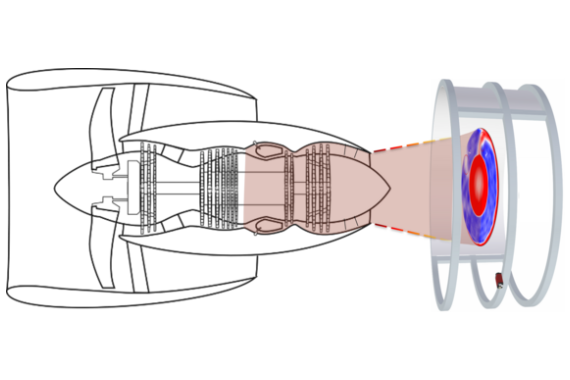

Over the course of their service life, turbines lose performance and efficiency, which makes efficient maintenance planning crucial. We therefore develop methods for identifying necessary maintenance measures by analyzing aerodynamic effects. To do this, we use AI-based approaches that automatically make damage predictions from comprehensive measurement data over the turbine's service life. We are also testing innovative maintenance methods, such as the Background-Oriented Schlieren method, to effectively detect burner failures in aircraft engines.

©

LUH/Sören Pinsdorf

©

LUH/Sören Pinsdorf

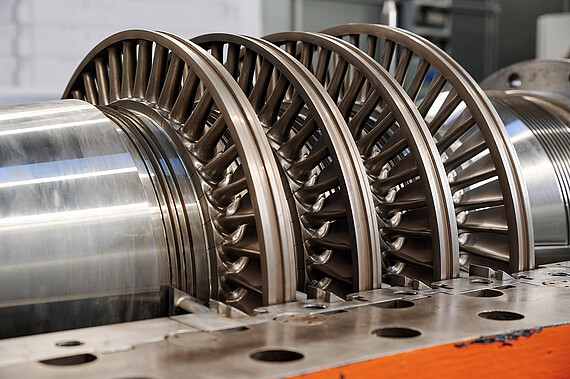

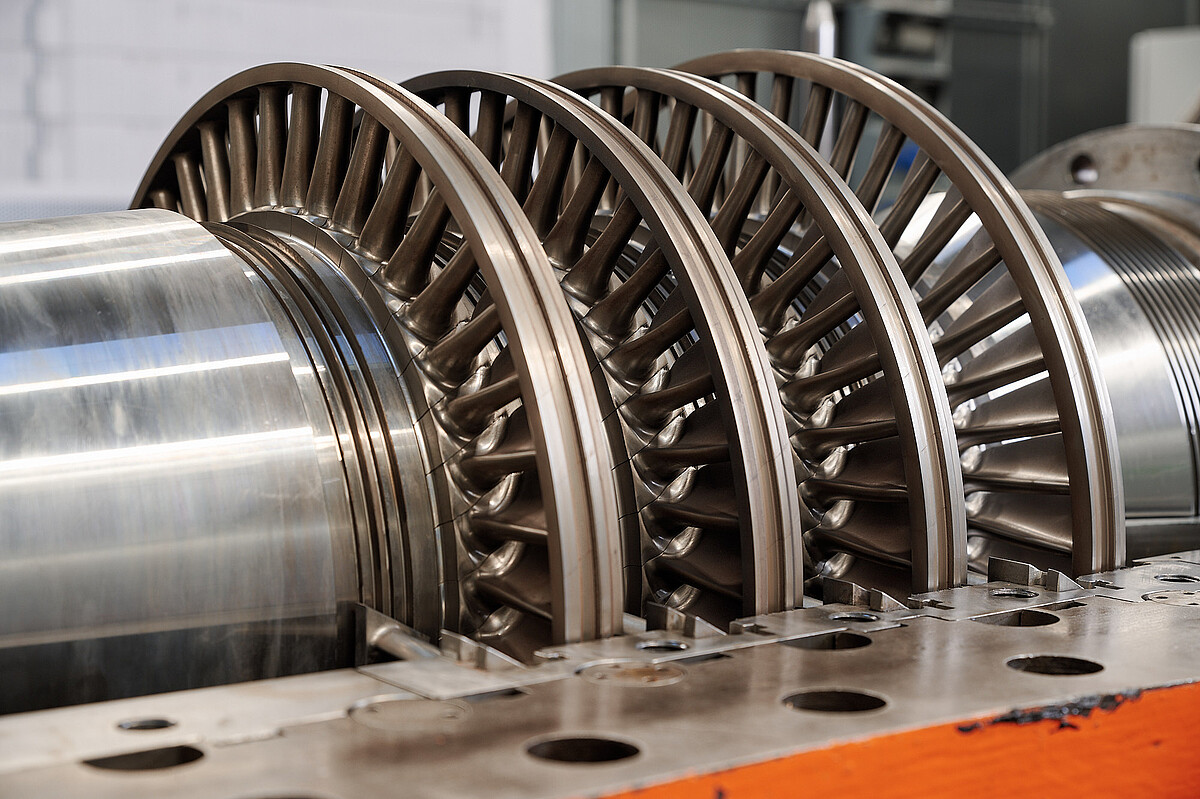

Experimental and numerical methods for the further development of gas turbines

We operate two axial turbine test benches for the experimental validation of our numerical research results. These enable comprehensive component testing for aviation, stationary gas turbines and steam turbines. Our test infrastructure allows us to carry out tests under machine-like parameters, which enables us to reproduce realistic test conditions. You can find more detailed information on our testing capabilities here.

Group Leader

30823 Garbsen