Description

Design methods for sustainable aircraft engines

Special compressors are required to supply air for the operation of fuel cells in aircraft. These compressors are the largest parasitic consumer and must therefore be designed as efficiently as possible. In the Compressor working group, we are therefore developing methods for the automated design and optimization of turbomachinery for this application. In addition to the actual flow control, particular attention is also paid to the water and heat management of the fuel cell systems, because only the joint optimization of the entire architecture leads to competitive systems.

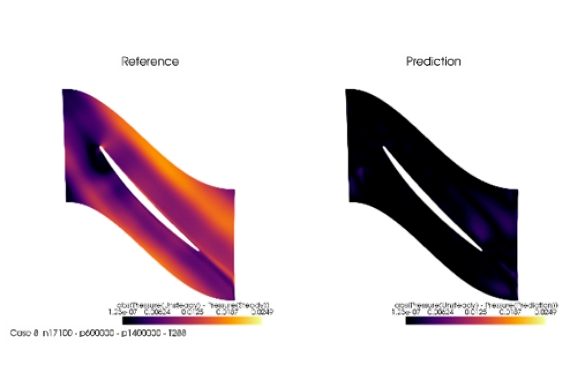

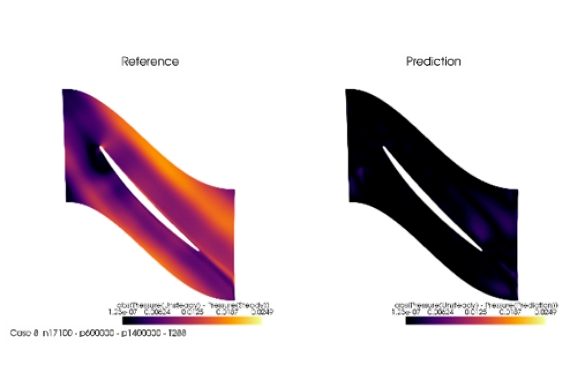

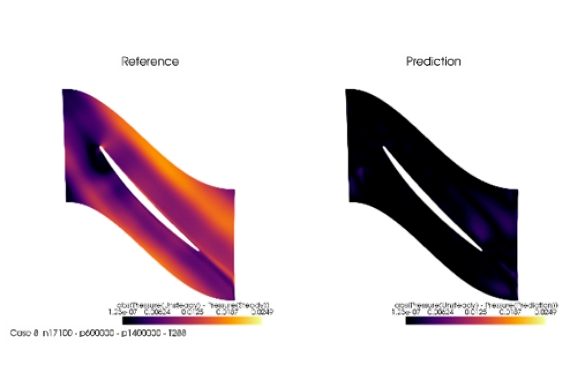

Machine learning

Design processes in aviation are developing in the direction of ever closer integration between the design models of the aircraft, drive system and drive components. Numerical flow simulations of turbomachinery components are often the bottleneck here due to the high computational effort involved. For this reason, we are developing deep learning methods in the compressor working group to accelerate flow and performance predictions in the compressor.

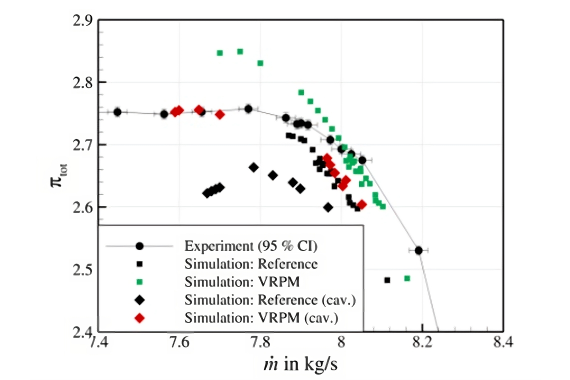

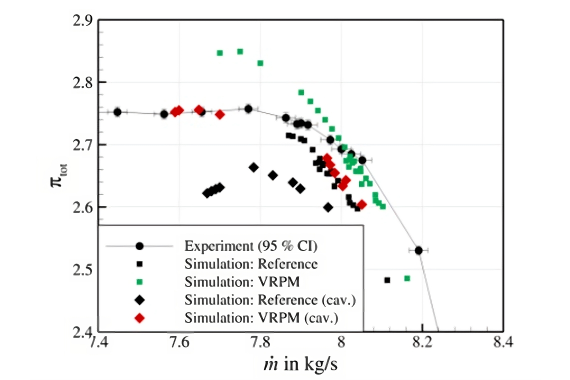

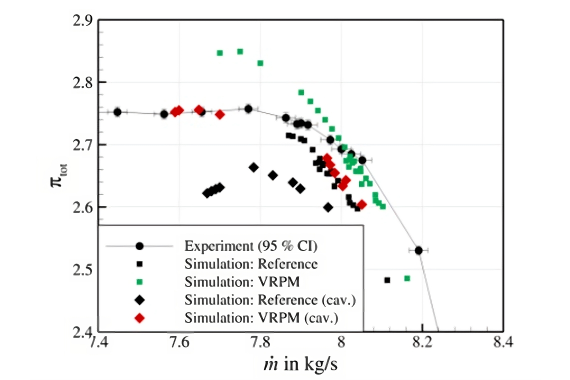

RANS modeling

Reynolds-averaged Navier-Stokes (RANS) calculation methods are still the workhorse of the industrial design of turbomachinery. In particular, the flow and performance prediction of compressors is especially challenging. The Compressors working group is therefore developing application-oriented RANS models to improve the prediction of rotational effects and unsteady flow influences.

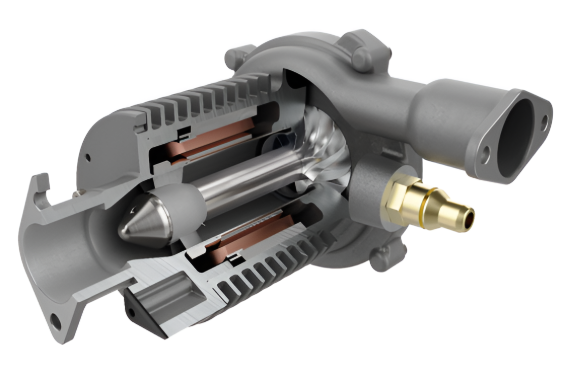

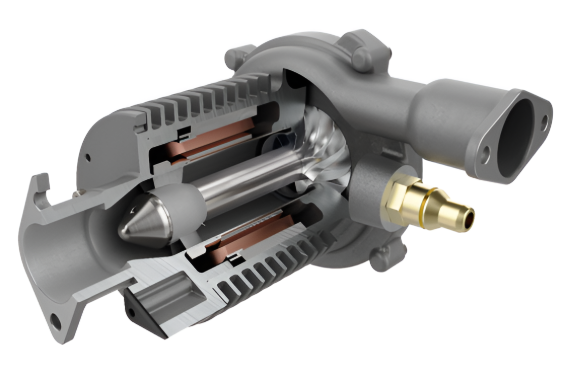

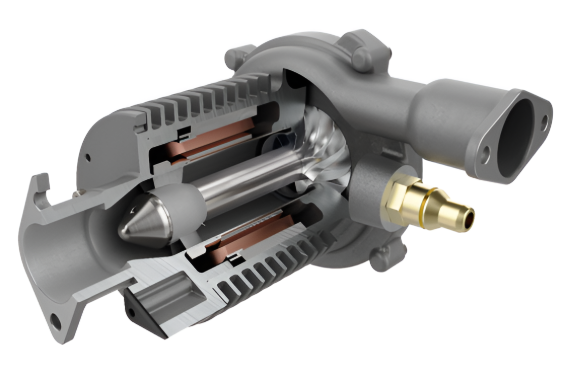

Components for fuel cell systems

For the realization of fuel cell systems for mobile and especially flying applications, the design of suitable components for the provision and conditioning of the working media is one of our areas of expertise. On the cathode side, we therefore develop application-specific compression systems. On the anode side of the fuel cell, compressors also contribute to increasing the service life and overall system efficiency by efficiently recirculating the unused hydrogen.

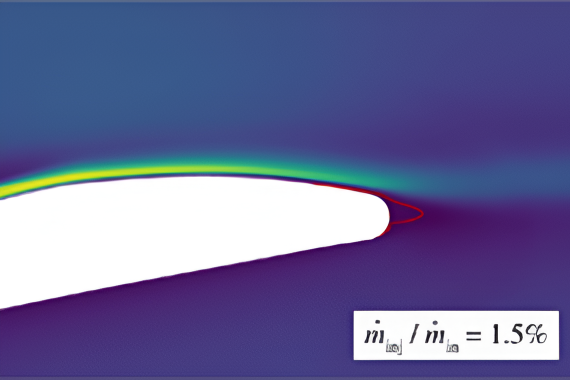

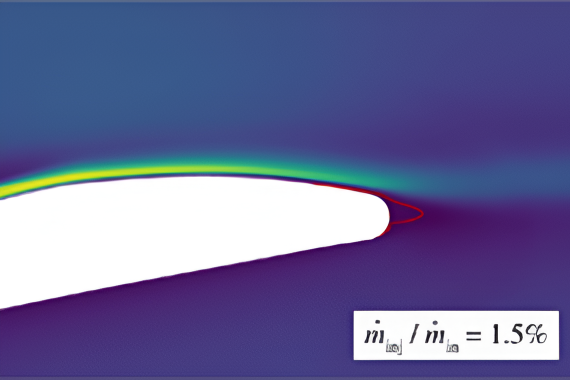

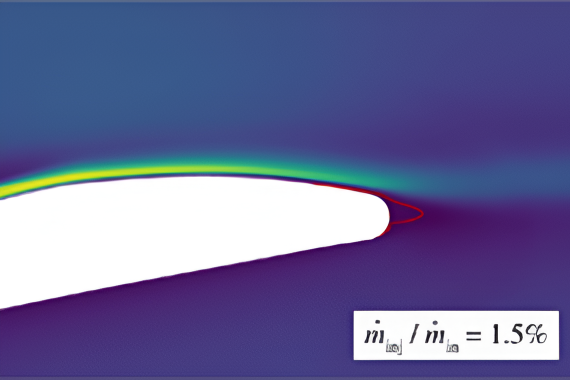

Active flow control

In order to achieve high compressor performance over a wide operating range, compressors are required that adapt to the operating conditions. Active Flow Control (AFC) includes several technologies, such as flow extraction and injection, which make it possible to influence blade loading, wake and secondary flow; these measures enable the development of adaptive compressors. The compressor working group is part of the Cluster of Excellence Sustainable and Energy Efficient Aviation (SE2A) to advance the state of the art of adaptive compressor design and to integrate this technology into comprehensive air transportation concepts with conventional, hybrid and fuel cell propulsion for long-, medium- and short-haul flights.

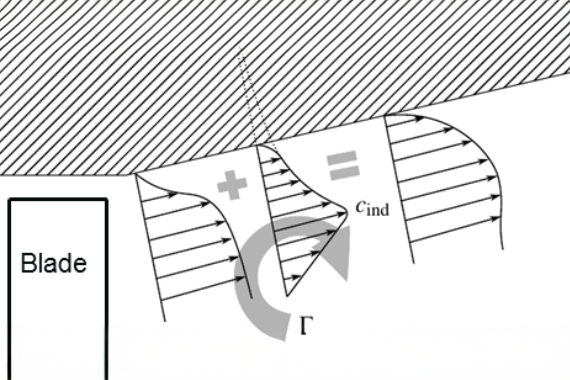

Component interactions

In real propulsion systems, turbomachinery performance is significantly influenced by adjacent components (e.g. inlet, diffuser). A comprehensive understanding of the interaction effects between adjacent components is therefore essential for the development of more efficient and robust propulsion systems.

Group management

30823 Garbsen