Field of Application

- Proof of principle for rotor blade vibrations measurements on wind turbines using Digital Image Correlation

- Validation of Digital Image Correlation measurements for rotating systems

- Experiment on flutter with rotating blades

Description

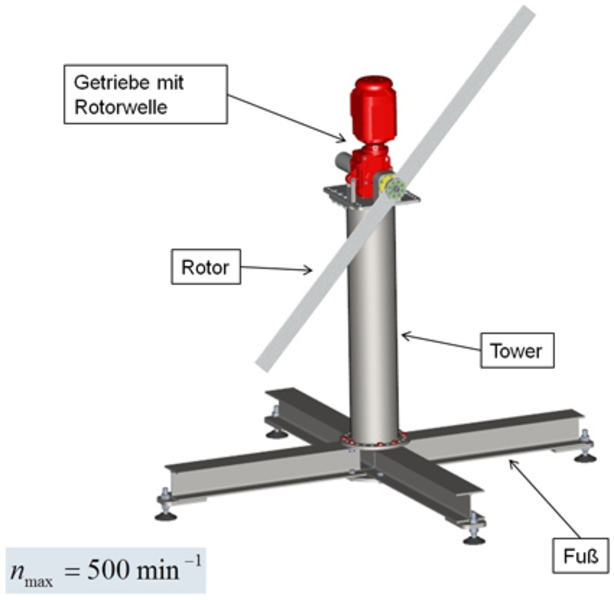

Each of the four bed-plates can be adjusted in height in order to provide a secure setup on uneven ground. The high mass of the I-beams ensures a stable stance even for a rotor with a significant imbalance.

Electrical signals from inside the rotating system can be transmitted through the hollow rotor shaft to the slip ring in the back. An incremental encoder is attached to the rotor shaft, which constantly provides the current rotor position and rotational speed. If the test bench becomes unstable during operation, an accelerometer will detect the vibrations and shutdown the entire system.

The blades of the test bench can be excited by an external impulse for low rotational speeds. For higher rotational speeds, each blade can be equipped with a piezo patch and excited by supplying high voltage current to the patch with the help of the slip ring. The slip ring can transmit a maximum voltage of 1500 V.

The electric drive is connected to the rotor shaft with a bevel drive. This setup allows a continuous adjustment of the rotational speed of the rotor from 10 – 500 rpm. The maximum rotor diameter for the current setup of the test bench is 2.2 m. However, with a new tower even larger rotors can be tested.

Measurement Techniques

- Digital Image Correlation (DIC)

- Strain gauges

- Laser distance sensors

Specifications

| Motor power | 1,5 kW |

| Maximum rotational speed: | 500 1/min |

| Number of test points inside rotating system | 6 |

| Rotational speed of the rotor shaft is monitored with an incremental encoder | |

| Maximum rotor diameter: 2,2 m | |